IoT in the chemical industry remains an untapped source of competitive edge, despite relentless competitive pressures and stringent safety and compliance regulations. With the right know-how this Industrial Internet of Things (IIoT), an ecosystem of connected devices, can deliver significant efficiency improvements to production processes. From precise data to actionable insights, Endress+Hauser technologies and expertise can unlock this potential for any chemical plant.

Key facts

47%

of automation executives say improving operational efficiency and productivity are the key drivers of IIoT adoption* *https://www.morganstanley.com/ideas/industrial-internet-of-things-and-automation-robotics

Find out how we can support your digitalization

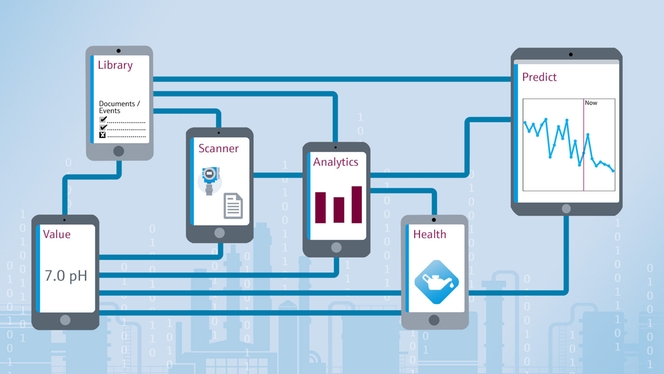

We help customers get more insights into their key business processes via a set of services that translate data into valuable information. Together, they build our Netilion IIoT ecosystem.

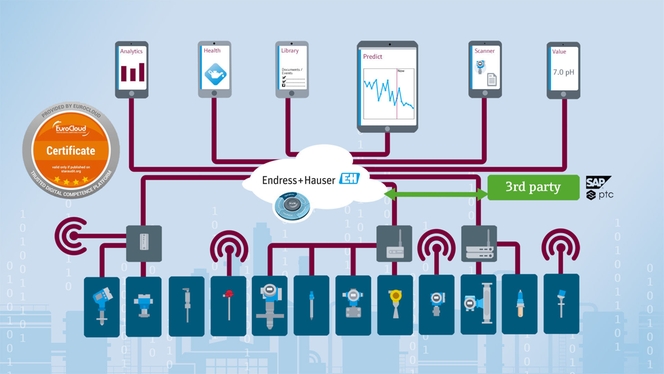

Our certified Netilion IIoT ecosystem for asset utilization and management is also open to third-party field devices and clouds.

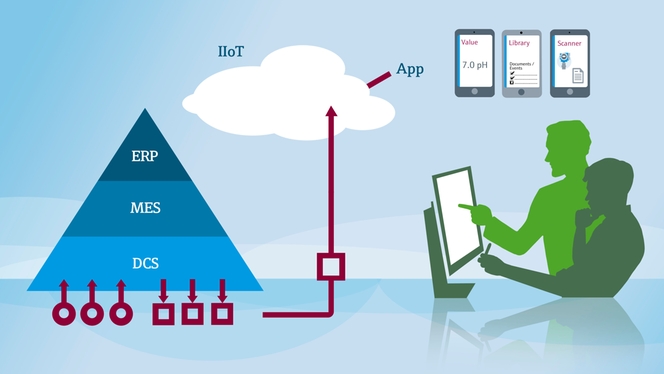

In line with Namur Open Architecture (NOA), our IIoT network creates a parallel channel that transfers data directly into the cloud – no need to touch the traditional plant architecture.

We help customers get more insights into their key business processes via a set of services that translate data into valuable information. Together, they build our Netilion IIoT ecosystem.

Our certified Netilion IIoT ecosystem for asset utilization and management is also open to third-party field devices and clouds.

In line with Namur Open Architecture (NOA), our IIoT network creates a parallel channel that transfers data directly into the cloud – no need to touch the traditional plant architecture.

Connect field instrumentation data to the cloud

Connectivity is the medium through which all information is exchanged and is thus vital for digitalization. It opens up unparalleled new possibilities for driving performance and safety, and yet can be complex to implement across the installed base.

Our expertise in the field

Endress+Hauser offers alternative approaches to connectivity, from cabled edge devices to Wi-Fi devices leveraging a SIM card.

- Bridge the gap between the field, your instruments and the Endress+Hauser cloud with the user-friendly and easy-to-install industrial edge device FieldEdge SGC500

- Connect directly to the Netilion cloud using devices equipped with a SIM card and unlock boundless new possibilities

Digitalize instrumentation with ease using the Scanner app

Taking full advantage of digitalization services at plant level requires establishing digital twins of all assets, and doing so with installed instrumentation not yet in the digital world can be a significant challenge for plant operators.

Our expertise in the field

The Endress+Hauser Netilion Scanner App enables digital twins of all installed assets to be created in no time, enabling seamless access to our full suite of Netilion services.

Combine data for actionable insights with Netilion Analytics

Maintenance managers have a multitude of KPIs to respect including number of suppliers and plant shutdowns. Monitoring and optimizing so many KPIs can be a difficult task, particularly in complex chemical plant operations.

Our expertise in the field

Combined with digital twins of the installed assets, Endress+Hauser Netilion Analytics enables convenient and accurate monitoring of all KPIs remotely and in real time, as well as the extraction of valuable insights for process improvements.

- Gain full transparency on the number of assets, manufacturers, obsolete devices and possible successors

- Analyze and monitor digital twins both automatically and continuously

- Generate live reports including concise analysis of your installed base

- Test Netilion Analytics for free

Solve errors rapidly with Netilion Health

When an unexpected error occurs, rapid action is vital to prevent costly downtime. Time can be lost searching through technical documentation for appropriate solutions.

Our expertise in the field

Netilion Health is a digital service that not only identifies and signals errors but also gives instructions on how to solve them.

- Access Netilion Health with the Field Xpert SMT70 tablet

- Solve errors remotely, avoiding direct field interventions

- Leverage Netilion health safely in the field and hazardous areas (Ex zone 2)

- Test Netilion Health for free

Data security you can rely on

Such is the competitive nature of the chemical industry; data security is a prime concern for plant operators leveraging IIoT.

Our expertise in the field

The Endress+Hauser IIoT offering is certified end to end for maximum data security. From the edge device to the customer data in the cloud, only leading safety mechanisms are employed:

- Encrypt your data with long key codes (HTTPS / TLS with SHA-256)

- Cooperate with certified data centers (e.g. ISO 27001)

- Rely on certification from an independent authority, licensed by “EuroCloud” with a 4-star rating

Benefits

Downtime and unplanned maintenance are a common issues in the chemical industry. IIoT and big data are offering exciting new possibilities to tackle these issues. Endress+Hauser has developed the concept and the tools to help our chemical customers start digitalizing their plants in a safe and simple way. With us as a long-term partner at your side, you can embrace the Industrial Internet of Things and start optimizing your manufacturing processes and driving worker productivity.

Key facts

30%

of assets installed in plants are obsolete and this leads to unplanned shutdowns.

Key facts

25'000

health conditions available for you.

Key facts

0 hours

of programming effort in the DCS/PLC thanks to automated update of replaced devices.

How we can help

The chemical industry is characterized by intense competition, nevertheless many plant operators are yet to fully explore the benefits hidden in the vast quantities of data produced by their field instrumentation. Comprising various IoT applications and algorithms, the Endress+Hauser Netilion ecosystem allows customers to turn field data into actionable insights for efficiency improvements, bypassing the automation pyramid.

- Gain in-depth insights into your installed base and make better data-driven decisions to optimize maintenance, production, operations and supply chain

- Create digital twins automatically via edge devices with a simple plug-and-play system, no need to touch your DCS

- Solve unexpected instrumentation errors remotely with your tablet or smartphone