Simplified quality control in distilleries

Waldbrand Distillery monitors alcohol concentration using Teqwave

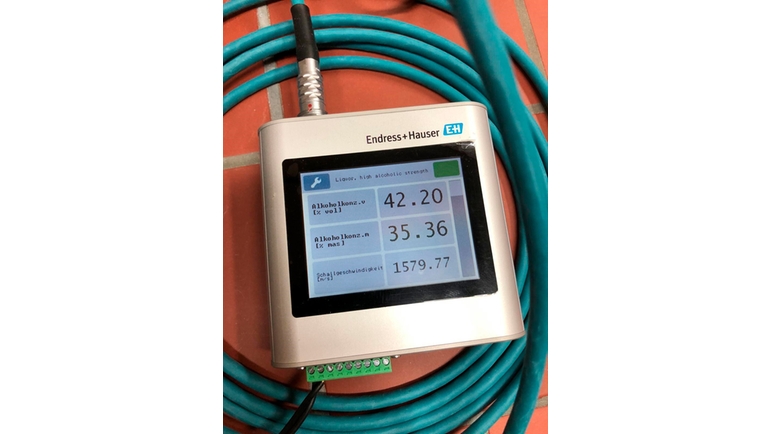

Waldbrand Destillerie now uses Teqwave from Endress+Hauser as a measuring device for monitoring alcohol concentration that can compensate for cross-influences from sugar or mineral content, enabling automatic measurement of the actual alcohol content. Teqwave also meets the requirement of being adaptable to beverage-specific properties. This makes it possible to continuously determine the alcohol content of distilled beverages accurately, even in the presence of sugar/invert sugar, acids, etc.

The result

-

Simultaneous and automatic concentration measurement of alcohol and sugar/invert sugar in distilled beverages with various concentration ranges thanks to preinstalled concentration data sets

-

Increased measuring accuracy even for difficult applications thanks to product-specific recipes and compensation for cross-influences such as mineral content, acid, etc.

-

Multivariable measurement for concentration of cleaning agents and disinfectants using only one measuring system

-

Simple cleaning of the sensor in the process

-

Reliable measuring performance with low maintenance effort

The customer requirement

Determining the alcohol concentration of distilled beverages before bottling ensures a consistently high product quality. Waldbrand GmbH previously measured the alcohol concentration manually, and adapted the alcohol content measurement for distilled beverages with sugar content via extensive manual calculations, a time-consuming and error-prone process. They wished to simplify the calculation of the actual alcohol concentration and a robust, accurate measuring device that is easy to clean.

Our solution

Teqwave can simultaneously measure alcohol and sugar/invert sugar concentration in distilled beverages. Preinstalled and beverage-specific concentration data sets enable plug-and-play measurements over various concentrations and temperatures; also recipes can be stored. This ensures consistently high accuracy and product quality, even under differing process conditions. The CIP capability of the sensor and the robust stainless-steel design enable simple cleaning in the process without removal.

Device used

The Ultrasonic concentration meter Teqwave I continuously measures the alcohol and sugar content of distilled beverages while taking various concentration data sets into account. These beverages include:

Gin, rum, fruit spirits

Single-malt whiskey with honey, etc."

-

Standard products

- Reliable, robust and low-maintenance

Technical excellence

Simplicity

-

Specialized products

- Designed for demanding applications

Technical excellence

Simplicity

Variable

| FLEX selections | Technical excellence | Simplicity |

|---|---|---|

Fundamental selection Meet your basic measurement needs |

Technical excellence

|

Simplicity

|

Lean selection Handle your core processes easily |

Technical excellence

|

Simplicity

|

Extended selection Optimize your processes with innovative technologies |

Technical excellence

|

Simplicity

|

Xpert selection Master your most challenging applications |

Technical excellence

|

Simplicity

Variable |