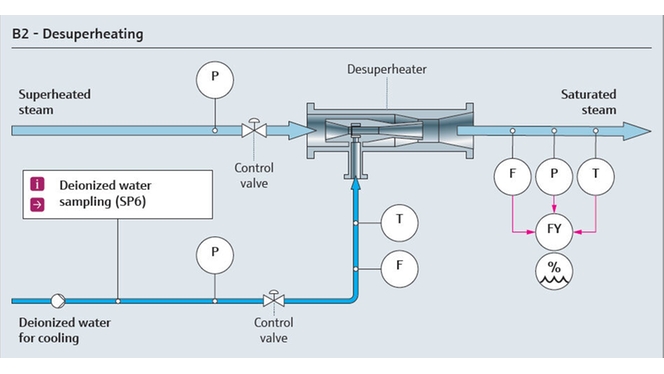

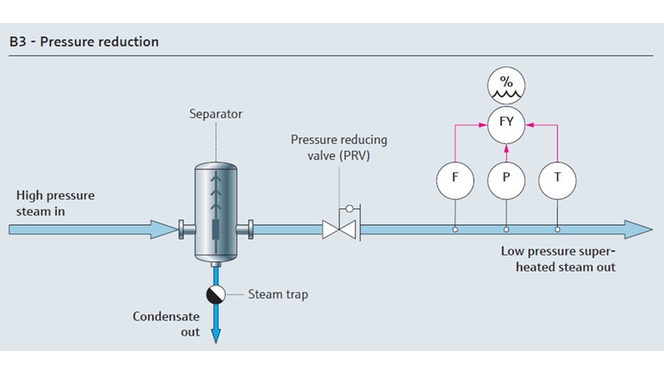

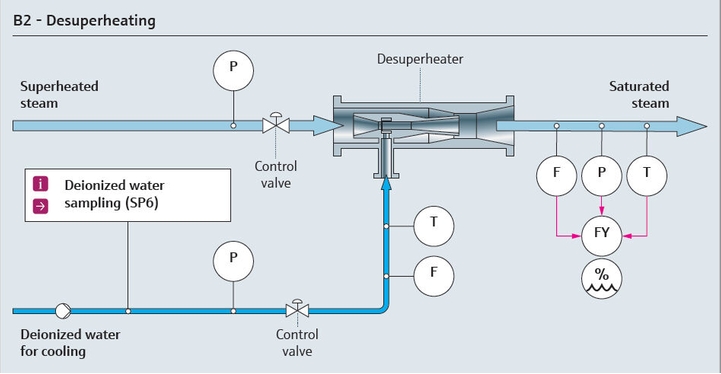

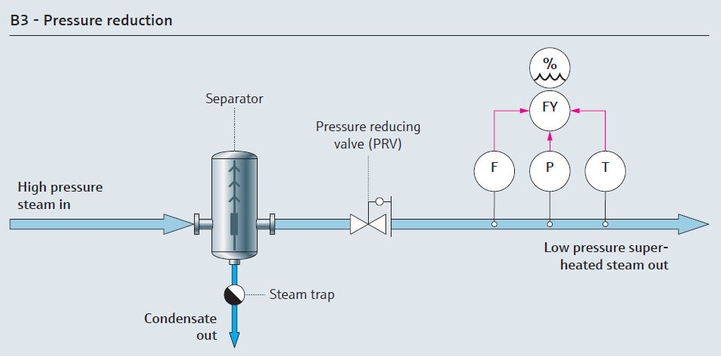

Steam distribution with minimal energy loss is a key challenge when aiming for efficient utilities plant operations. From the boiler house to the points of end-use, poor lagging, malfunctioning steam traps, and inefficient cooling of superheated steam can diminish energy distribution effectiveness. Water hammer can cause wear to infrastructure. Therefore, dryness fraction must be constantly and accurately monitored for optimal steam quality. Our technologies help to optimize steam distribution.

Key facts

50 to 100%

measuring error if compensating superheated steam downstream of a pressure reducing valve by temperature only (mistaken as saturated steam)

Key measuring points in steam distribution

Precise steam pressure measurement

Precise steam pressure measurement is vital to ensuring optimal process conditions. Controlled by pressure, process temperature must be neither too high, causing product losses, nor so low that sterilization does not occur.

Our expertise in the field

Endress+Hauser offers a broad portfolio of highly accurate pressure measurement instrumentation highly suited to steam applications in utilities.

Corrosion and inhibitor cost reduction

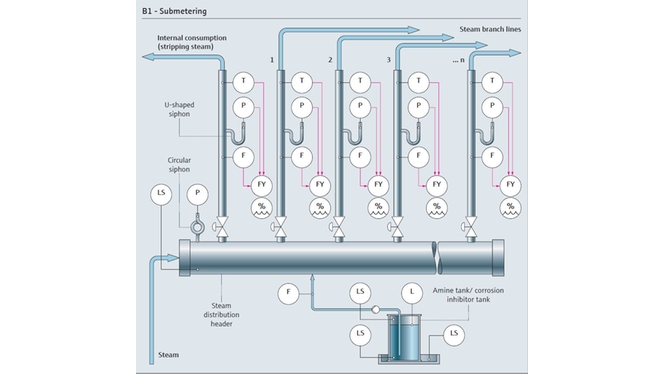

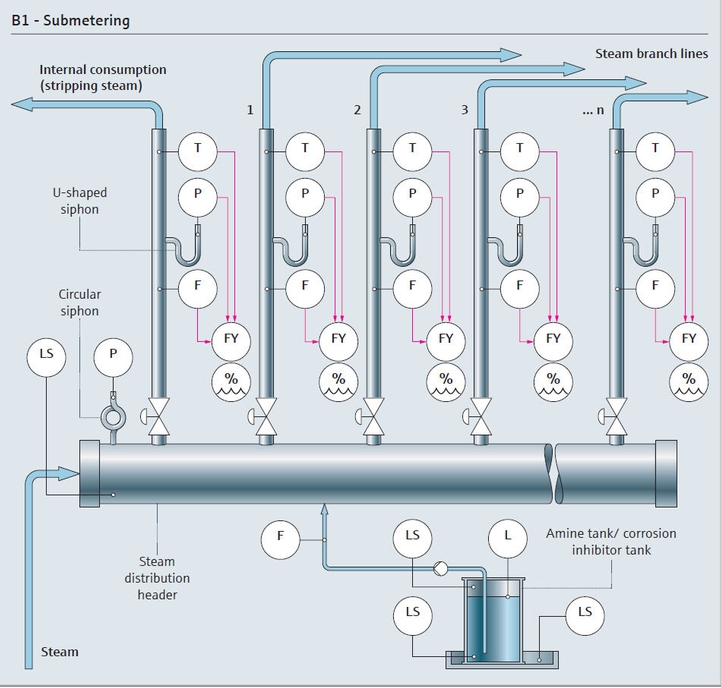

Corrosion is a persistent challenge in all steam distribution systems, heightening the risk of costly downtime due to equipment failure. Whereas adding amines can help reduce the risk of corrosion, such additives can themselves be costly and require precise metering and good inventory management.

Our expertise in the field

Endress+Hauser offers sound measuring systems to guarantee optimal inventory management.

- Measure amine consumption with ± 0.1% o.r. accuracy using our compact Promass A flowmeter

- Monitor amine tank levels accurately to ensure timely re-ordering

- Protect your equipment from corrosion efficiently

Steam availability protection

Continued steam availability at the required process parameters is essential. A failure in the steam supply system can result in total production shutdown, bringing serious financial consequences.

Our expertise in the field

The Endress+Hauser portfolio contains a complete range of monitoring technologies to ensure that steam supply is protected, process parameters are sustained, and shutdown risk is minimized.

- Monitor steam temperature with our robust Omnigrad thermometers

- Protect your steam distribution header using our Liquiphant switch line

- Control cooling water quality in desuperheaters using Liquiline pH, DO and conductivity sensors

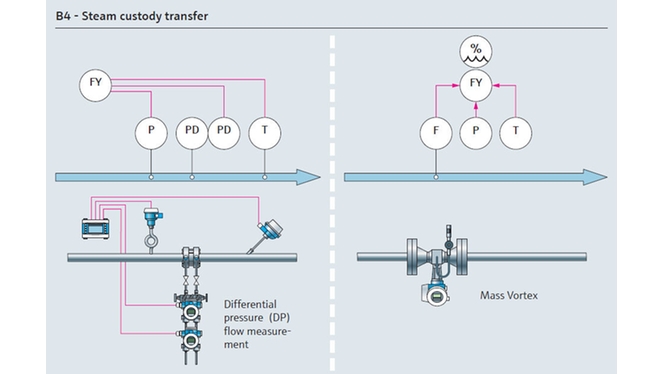

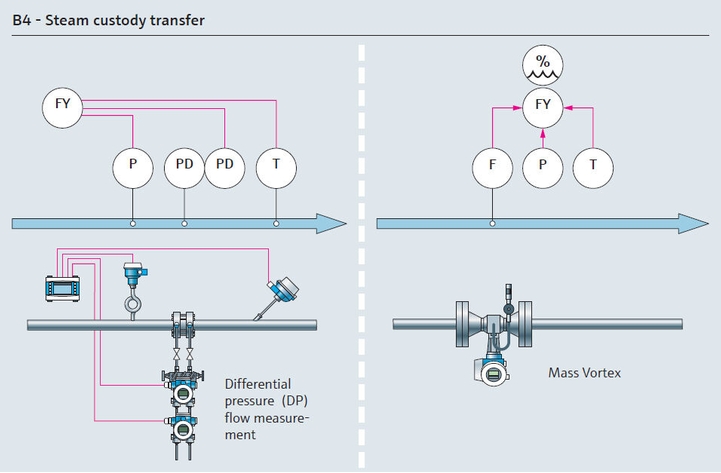

Transparent steam custody transfer

As only dry steam enables process maximization, it is essential for utilities plant managers to be able to know the energy content of the steam they are receiving when purchasing steam from an external source.

Our expertise in the field

Endress+Hauser offers Prowirl, a single, integrated steam metering system enabling steam quality to be continuously monitored on reception for optimal processes and transparent supplier relationships.

- Monitor flow, temperature and pressure within a separate flow computer

- Determine whether and to what extent steam is superheated, wet, or dry saturated

- Compensate energy and mass correctly, also by the dryness fraction

Accurate steam energy measurement

Inaccurate or uncertain measurements of energy consumption and loss at the various points within a steam distribution system can lead to incorrect conclusions and misguided actions for optimization. Utilities plant managers must be able to rely on accurate measurements.

Our expertise in the field

Based on in-depth energy measurement and calibration expertise, the Endress+Hauser Energy Measurement Proving Service enables energy measurement accuracy to be checked and confirmed.

- Rely on Endress+Hauser experts for on-site calibration and verification of field devices with minimal or no process interruption

- Understand the overall uncertainty of your energy measurement

- Gain clear recommendations on how to improve accuracy of the energy measurement loop

Benefits

Balancing steam distribution and steam consumption systems requires a great deal of skill and know-how. Our extensive range of accurate and reliable metering, monitoring, and steam management products and services ensures complete transparency and efficient, safe steam distribution in compliance with energy and environmental management standards. Partner with us for integrated steam management solutions that unlock the maximum potential of your entire steam system.

Key facts

Up to 15%

energy consumption savings from comprehensive energy monitoring solutions

Key facts

24/7

high measuring accuracy and operational safety over the entire life cycle of your steam system

Key facts

10s of millions

of savings from sensors and solutions successfully applied in utilities

How we can help

From reducing the risk of water hammer, to ensuring efficient cooling of superheated steam, to checking that steam dryers and pressure reducing valves are functioning correctly, Endress+Hauser enables you to accurately measure and optimize steam distribution, including custody transfer. Our complete portfolio of 2-wire measurement and monitoring solutions will increase the availability of your steam supply and allow exact mass and energy balance for safe, efficient steam distribution.

- Improve process efficiency with accurate energy distribution monitoring

- Reduce corrosion risk with cooling water quality and amine consumption monitoring

- Comply with international standards thanks to Endress+Hauser Heartbeat Technology